Appendix XI E. Essential Oils in Herbal Drugs

The determination of essential oils in herbal drugs is carried out by steam distillation in a special apparatus in the conditions described below. The distillate is collected in the graduated tube, using xylene to take up the essential oil; the aqueous phase is automatically returned to the distillation flask.

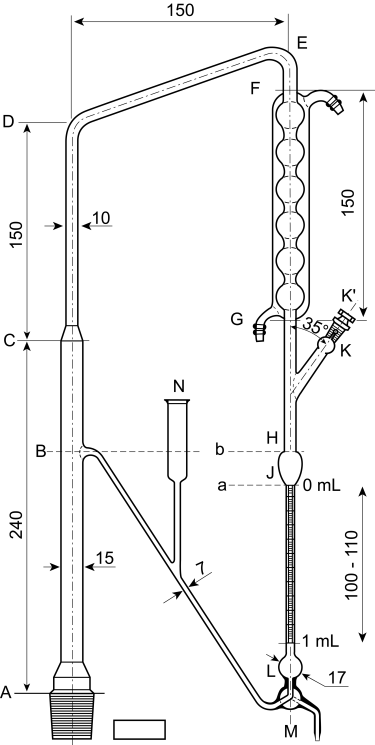

Apparatus The apparatus comprises the following parts:

Method Use a thoroughly cleaned apparatus. Carry out the assay according to the nature of the drug to be examined. Place the prescribed volume of distillation liquid in the flask, add a few pieces of porous porcelain and attach the condenser assembly. Introduce water R through the filling funnel N until it is at the level B. Remove the stopper K′ and introduce the prescribed quantity of xylene R, using a pipette with its tip at the bottom of the tube K. Replace the stopper K′ and ensure that the orifice coincides with the vent. Heat the liquid in the flask to boiling and adjust the distillation rate to 2-3 mL/min, unless otherwise prescribed.

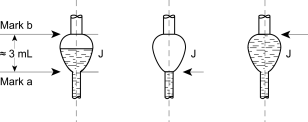

To determine the rate of distillation, during distillation lower the level of the water by means of the three-way tap until the meniscus is at the level of the lower mark (a) (see Figure 2.8.12.-2). Close the tap and measure the time taken for the liquid to reach the upper mark (b). Open the tap and continue the distillation, modifying the heat to regulate the distillation rate. Distil for 30 min. Stop the heating and after at least 10 min read off the volume of xylene in the graduated tube.

Introduce into the flask the prescribed quantity of the drug and continue the distillation as described above for the time and at the rate prescribed. Stop the heating and after 10 min read the volume of liquid collected in the graduated tube and subtract the volume of xylene previously noted. The difference represents the quantity of essential oil in the mass of the drug taken. Calculate the result as millilitres per kilogram of drug.

When the essential oil is to be used for other analytical purposes, the water-free mixture of xylene and essential oil may be recovered as follows: remove the stopper K′ and introduce 0.1 mL of a 1 g/L solution of sodium fluoresceinate R and 0.5 mL of water R. Lower the mixture of xylene and essential oil into the bulb-shaped swelling L by means of the three-way tap, allow to stand for 5 min and lower the mixture slowly until it just reaches the level of the tap M. Open the tap anti-clockwise so that the water flows out of the connecting tube BM. Wash the tube with acetone R and with a little toluene R introduced through the filling funnel N. Turn the tap anti-clockwise in order to recover the mixture of xylene and essential oil in an appropriate flask.