Appendix XI T. Herbal Drugs: Sampling and Sample Preparation

In order to reduce the effect of sampling in qualitative and quantitative analysis, it is necessary to ensure that the composition of the sample used is representative of the batch of material being examined. The following procedures are the minimum considered applicable for herbal drugs. NOTE: other procedures may be used if they can be demonstrated to produce representative batch samples.

Bulk Sample

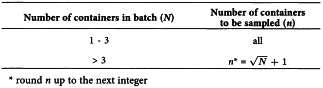

Where external examination of containers, markings and labels of a batch indicate that it can be considered to be homogeneous, sample the number of randomly selected containers indicated below. Where a batch cannot be considered to be homogeneous, divide it into sub-batches that are as homogeneous as possible, then sample each sub-batch as a homogeneous batch using, as a minimum, the number of randomly selected containers indicated below.

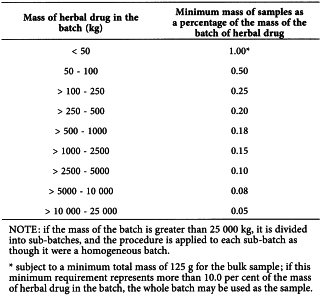

Take one sample from each container to be sampled. The sample is taken from the upper, middle or lower section of the container, such that the samples taken are representative of different parts of the containers. In the case of large bales or bags, samples must be taken from a depth of at least 10 cm. The mass of the material taken from each container is such that the total mass of the bulk sample complies with the following values.

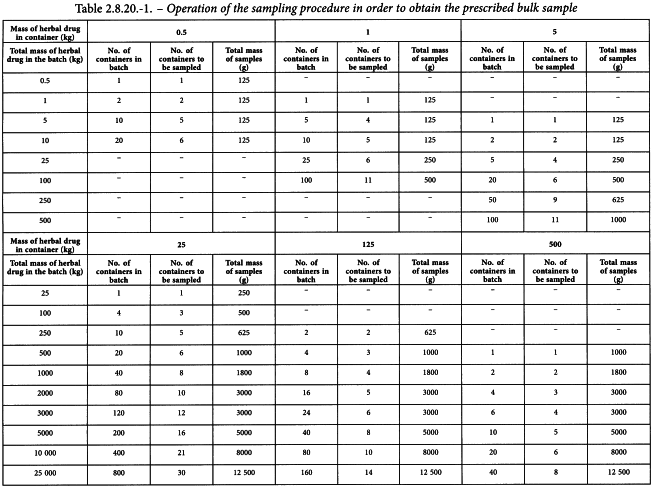

Prepare the bulk sample by combining and thoroughly mixing the samples taken from each of the randomly selected containers (see Table 2.8.20.-1).

Test sample

Unless otherwise prescribed in the monograph, prepare the test sample as follows.

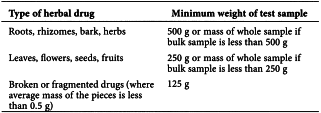

Reduce the size of the bulk sample by quartering (see Note below) or by any other method that produces a homogeneous sample, making sure that each retained portion remains representative of the whole, until the minimum retained quantity complies with the following conditions.

NOTE: quartering consists of placing the bulk sample, thoroughly mixed, as a level and square-shaped heap and dividing it diagonally into 4 equal parts. 2 opposite quarters are retained and carefully remixed. The process is repeated as necessary until the required minimum mass is obtained for the test sample.

Mill the test sample in a single pass through a 1 mm screen or the screen size specified in the monograph. The use of a milling machine is recommended.

Pass the milled sample through a 1 mm standard sieve or the sieve specified in the monograph. The residue retained on the sieve must not be more than 10 per cent of the total mass of the milled sample, of which not more than 2 per cent of the total mass of the milled sample may be of a particle size greater than 1.5 mm or 1.5 times the specified particle size in the monograph. If these conditions are met, the sample and residue are to be well mixed to form the test sample for analysis.

In those cases where these requirements are not met, the test sample for analysis is composed of the 2 parts measured separately. Therefore, the quantity required for each analysis is derived by weighing proportional quantities of the powder and the residue.

NOTE: for determination of microscopic characters, a portion of the milled test sample is re-milled through a 0.355 mm screen.