Appendix XVII G. Friability

1. Uncoated Tablets1

This chapter provides guidelines for the friability determination of compressed, uncoated tablets. The test procedure presented in this chapter is generally applicable to most compressed tablets. Measurement of tablet friability supplements other physical strength measurements, such as tablet breaking force.

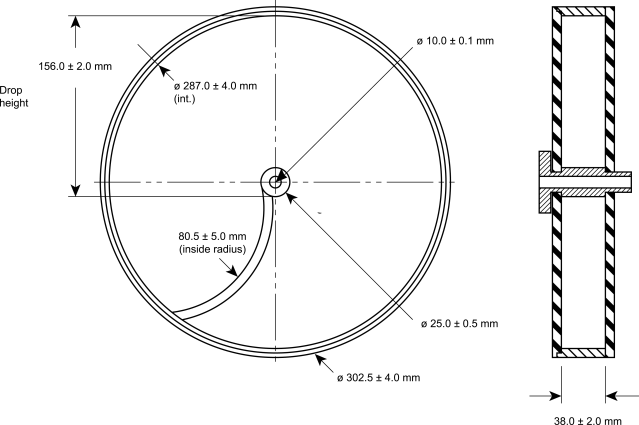

Use a drum, with an internal diameter between 283-291 mm and a depth between 36-40 mm, of transparent synthetic polymer with polished internal surfaces, and subject to minimum static build-up (see Figure 2.9.7.-1.). One side of the drum is removable. The tablets are tumbled at each turn of the drum by a curved projection with an inside radius between 75.5-85.5 mm that extends from the middle of the drum to the outer wall. The outer diameter of the central ring is between 24.5-25.5 mm. The drum is attached to the horizontal axis of a device that rotates at 25 ± 1 r/min. Thus, at each turn the tablets roll or slide and fall onto the drum wall or onto each other.

For tablets with a unit mass equal to or less than 650 mg, take a sample of whole tablets corresponding as near as possible to 6.5 g. For tablets with a unit mass of more than 650 mg, take a sample of 10 whole tablets. The tablets are carefully dedusted prior to testing. Accurately weigh the tablet sample, and place the tablets in the drum. Rotate the drum 100 times, and remove the tablets. Remove any loose dust from the tablets as before, and accurately weigh.

Generally, the test is run once. If obviously cracked, cleaved, or broken tablets are present in the tablet sample after tumbling, the sample fails the test. If the results are difficult to interpret or if the weight loss is greater than the targeted value, the test is repeated twice and the mean of the 3 tests determined. A maximum loss of mass (obtained from a single test or from the mean of 3 tests) not greater than 1.0 per cent is considered acceptable for most products.

If tablet size or shape causes irregular tumbling, adjust the drum base so that the base forms an angle of about 10° with the horizontal and the tablets no longer bind together when lying next to each other, which prevents them from falling freely.

Effervescent tablets and chewable tablets may have different specifications as far as friability is concerned. In the case of hygroscopic tablets, a humidity-controlled environment is required for testing.

A drum with dual scooping projections, or apparatus with more than one drum, for the running of multiple samples at one time, are also permitted.

2. Granules and Spheroids

This chapter describes 2 methods for determination of the friability of granules and spheroids, which may be used during development studies. It is recognised, however, that many methods with equal suitability may be used.

This test is intended to determine, under defined conditions, the friability of granules and spheroids. Friability is defined as a reduction in the mass of the granules or spheroids or in the formation of fragments of granules or spheroids, occurring when the granules or spheroids are subjected to mechanical strain during handling (tumbling, vibration, fluidisation, etc.). Examples of changes are abrasion, breakage or deformation of granules or spheroids.

METHOD A

Apparatus (fluidised-bed apparatus)

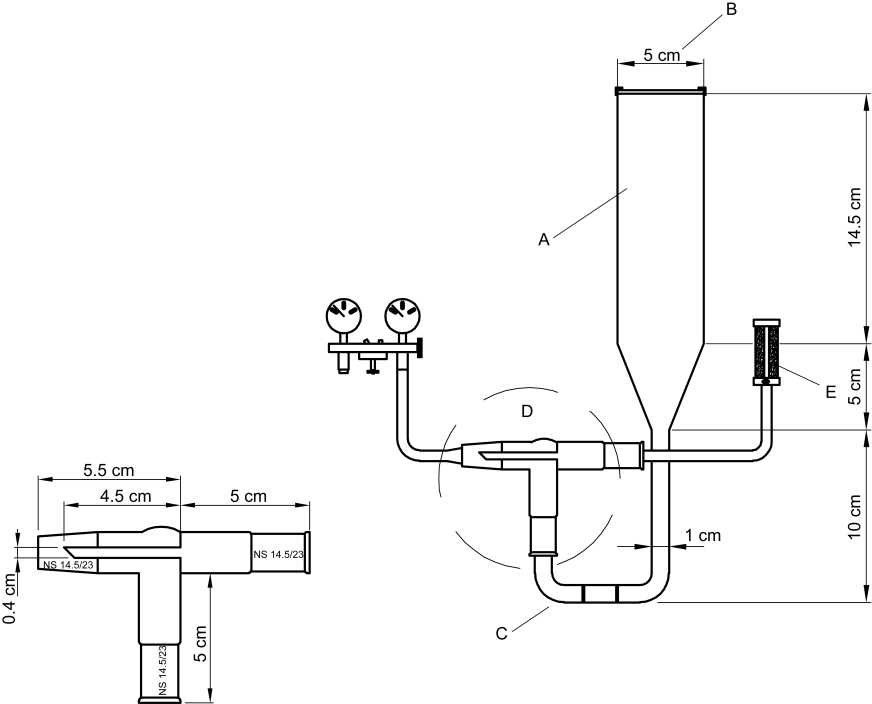

The apparatus (see Figure 2.9.41.-1) consists of a glass cylinder (A) with a conical lower part. The cylinder is provided with a sieve lid (B) having an aperture size of 500 µm or any other suitable sieve. The conical end is connected to a U-shaped glass tube (C) that can be disconnected from the cylinder for removal of the granules or spheroids. The U-tube is attached to a T-coupling (D). One inlet of the T-coupling is joined by a silicone tube to a manometer for regulating the compressed-air flow (use compressed air complying with the test for water in the monograph Medicinal air (1238)), the other one is connected via a silicone tube to a by-pass flowmeter (E) (0.10-1.00 m3⋅h-1).

Procedure

The following procedure is usually suitable Remove the fine particles by sieving (sieve having an aperture size of 710 µm or any other suitable sieve). Introduce about 8.0 g (m1) of granules or spheroids into the cylinder (A). Close the apparatus with the sieve lid (B). Adjust the flow rate of the compressed air to 0.45 m3⋅h-1. After 15 min, remove the granules or spheroids from the apparatus by disconnecting the U-tube and weigh again (m2). Test 3 samples and calculate the mean value. It is recommended to spray the inside of the apparatus with an antistatic agent every 3 determinations in order to prevent electrostatic charging.

Loss on drying Dry in an oven at 105 °C, unless otherwise prescribed. Alternatively, other drying conditions as described in general chapter 2.2.32 may be used.

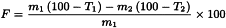

Calculation

F | = | friability; |

T1 | = | percentage loss on drying before the test (mean of 2 determinations); |

T2 | = | percentage loss on drying after the test (mean of 2 determinations); |

m1 | = | mass of the granules or spheroids before the test, in grams; |

m2 | = | mass of the granules or spheroids after the test, in grams. |

METHOD B

Apparatus (oscillating apparatus)

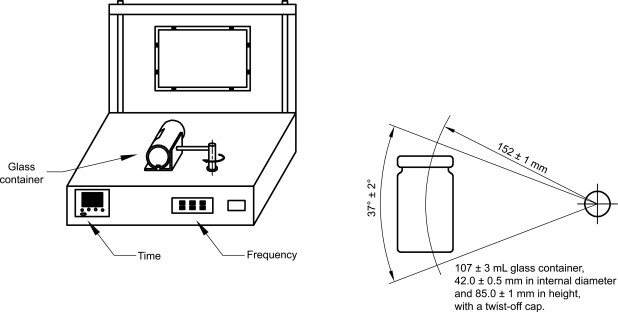

The apparatus (see Figure 2.9.41.-2) consists of a glass container, containing the granules or spheroids to be examined, which is subjected to horizontal oscillations. The frequency and duration of the oscillations can be varied continuously. The frequency can be adjusted, using a scale, to a value in the range 0-400 oscillations/min. The duration can be set to a value in the range 0-9999 s.

Procedure

The following procedure is usually suitable Remove the fine particles by sieving (sieve having an aperture size of 355 µm or any other suitable sieve). In the glass container, weigh about 10.00 g (m1) of the granules or spheroids. Install the container in the apparatus. Shake for 240 s at the highest frequency for hard granules or spheroids, or for 120 s at a lower frequency (e.g. 140 oscillations/min) for soft granules or spheroids. Sieve (355 µm, or the same sieve as used previously) and weigh the granules or spheroids again (m2). Test 3 samples and calculate the mean value.

Loss on drying Dry in an oven at 105 °C, unless otherwise prescribed. Alternatively, other drying conditions as described in general chapter 2.2.32 may be used.

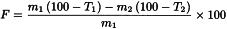

Calculation

F | = | friability; |

T1 | = | percentage loss on drying before the test (mean of 2 determinations); |

T2 | = | percentage loss on drying after the test (mean of 2 determinations); |

m1 | = | mass of the granules or spheroids before the test, in grams; |

m2 | = | mass of the granules or spheroids after the test, in grams. |