Chemical Precursors for Radiopharmaceutical Preparations

Ph Eur

DEFINITION AND SCOPE

Chemical precursors for radiopharmaceutical preparations, hereinafter referred to as ‘chemical precursors’, are non-radioactive substances obtained by chemical synthesis for combination with a radionuclide.

Where a chemical precursor not described in an individual monograph of the European Pharmacopoeia is used in a radiopharmaceutical preparation prepared for the special needs of individual patients, the need for compliance with this general monograph is decided in the light of a risk assessment.

This risk assessment takes account of:

Where chemical precursors are manufactured using substances of human or animal origin, the requirements of chapter 5.1.7. Viral safety apply.

Where chemical precursors are obtained from animals susceptible to transmissible spongiform encephalopathies other than by experimental challenge, where applicable, they also comply with the requirements of the general monograph Products with risk of transmitting agents of animal spongiform encephalopathies (1483).

PRODUCTION

Chemical precursors are prepared by procedures designed to ensure a consistent quality and provide compounds that comply with the requirements of the individual monograph or approved specifications. Chemical precursors must be produced within the framework of a suitable quality system.

CHARACTERS

The statements under the heading Characters (e.g. statements about the solubility or a melting point) are not to be interpreted in a strict sense and are not requirements. They are given for information.

IDENTIFICATION

Appropriate analytical methods, such as nuclear magnetic resonance spectrometry, infrared absorption spectrophotometry, mass spectrometry and chromatographic methods are used to provide confirmation of the identity of the chemical precursor.

TESTS

Related substances

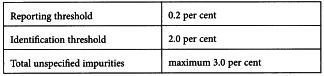

Unless otherwise prescribed or justified and authorised, organic impurities in chemical precursors and inorganic impurities present in inorganic chemical precursors are to be reported, identified and controlled as follows:

Specific thresholds may be applied for impurities known to be unusually potent or to produce toxic or unacceptable pharmacological effects.

If the individual monograph does not provide suitable control for a new impurity, a suitable test for control must be developed and included in the specification for the substance.

Residual solvents

Residual solvents are limited according to the principles defined in chapter 5.4 using general method 2.4.24 or another suitable method.

Class 1 solvents must not be employed in the final step of the manufacturing process of chemical precursors. If the use of a Class 1 solvent in an earlier step in the production process is unavoidable, the limits stated in chapter 5.4, Table 1 apply.

Based on the permitted daily exposure (PDE), Class 2 and Class 3 solvents are limited to 0.5 per cent.

For Class 2 and Class 3 solvents, a test for loss on drying or a specific determination of the solvent may be carried out. If for a Class 2 or a Class 3 solvent, a justified and authorised limit greater than 0.5 per cent is prescribed, a specific determination of the solvent is required.

Metal catalysts or metal reagent residues

If the production processes of chemical precursors are known or suspected to lead to the presence of metal residues due to the use of a specific metal catalyst or metal containing reagent, the chemical precursors comply with the limit of 0.01 per cent for each of the following metals: Pt, Pd, Ir, Rh, Ru, Os, Mo, Ni, Cr, V, Pb, Hg, Cd and Tl, unless stricter limits are stated in an individual monograph.

The methodology described in general chapter 2.4.20. Determination of metal catalyst or metal reagent residues is to be applied wherever possible.

Microbial contamination

TAMC: acceptance criterion 103 CFU per gram for bulk material or maximum 102 CFU per container for chemical precursors packed in single and multidose containers (2.6.12).

TYMC: acceptance criterion 102 CFU per gram for bulk material or maximum 101 CFU per container for chemical precursors packed in single-dose and multidose containers (2.6.12).

Bacterial endotoxins (2.6.14)

Unless otherwise justified and authorised, bacterial endotoxins are limited to a maximum 100 IU per gram for bulk material or maximum 10 IU per container for chemical precursors packed in single-dose and multidose containers.

ASSAY

Unless otherwise justified and authorised, the content of chemical precursors for radiopharmaceutical preparations is determined using a suitable method.

STORAGE

Store chemical precursors in an airtight container and in conditions that ensure adequate stability.

LABELLING

The labelling of chemical precursors complies with the relevant national and European legislation where relevant information is available. The label indicates the intended use as a chemical precursor for radiopharmaceutical preparations.

The accompanying information may recommend testing the substance in one or more production runs before its use for the manufacture of radiopharmaceutical preparations to ensure that, under specified production conditions, the substance yields a radiopharmaceutical preparation in the desired quantity and of the quality specified.

Ph Eur